Modeling

Early in the development of a geothermal project, there may be uncertainty regarding the potential of the resource to generate power. GDA has developed computer models to allow quick estimation of the power output from various types of plant, given key assumptions about the characteristics of the resource. GDA can customize a model to predict power output of a specific plant, or a specific unit within a plant. In this way, plant operators can compare predicted performance to actual performance to identify areas of focus for improvement or optimization. If you are interested in a custom model, please contact us.Please select a type of plant to begin:

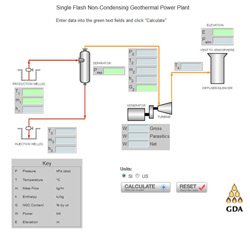

Single-Flash / Non-Condensing / Atmospheric Discharge

Single-Flash / Non-Condensing / Atmospheric Discharge

This is a great starter plant due to low initial cost and the high potential for modular construction. A modular plant is much more portable, allowing for early wellhead power generation while the balance of the wellfield is developed for a large project. In this type of plant, steam is expanded through the turbine and then released to atmosphere without being condensed.

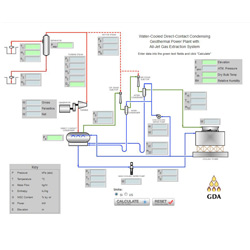

Single-Flash / Condensing / All-Jet Gas Extraction / Counter-Flow Water Cooling

A condensing plant makes better use of the resource than a non-condensing plant. In this model, steam is expanded through the turbine down to a very low pressure. Hence, much more power can be generated from the same steam flow when compared with non-condensing plants. After leaving the turbine the steam encounters cooling water sprays in a direct contact condenser. The heat gained by the cooling water in the condensing process is typically released to atmosphere in a cooling tower. Gases contained in the steam that do not condense are removed with a 2-stage steam jet gas extraction system and released to atmosphere.

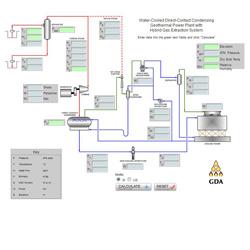

Single-Flash / Condensing / Hybrid Gas Extraction / Counter-Flow Water Cooling

This process model is similar to the plant above but uses a different means of gas extraction. In this model, a hybrid gas extraction system is used. The hybrid system consists of a first-stage steam jet followed by a second stage vacuum pump. This generally improves the steam rate as compared to the all-jet gas extraction system, but the improvement comes with a cost.

Binary / Brine Resource / Air Cooling

A binary cycle generally finds an advantage over flashed steam cycles where the geothermal fluid temperature is below 150 C (302 F). The most common binary cycle is the Organic Rankine Cycle where heat is transferred from the geothermal fluid to a secondary working fluid that generally boils at a lower temperature than water. The working fluid vapor is then expanded in a turbine which drives a generator to produce power. Finally, the working fluid vapor is condensed back to liquid form and then pumped back into the heat exchangers to repeat the cycle.

Typical working fluids include isobutane, isopentane, R134a, and R245fa.

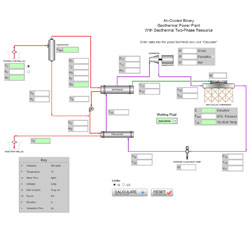

Binary / Two-Phase Resource / Air Cooling

This process model is similar to the model above but uses a two-phase geothermal resource instead of pumped brine. In this model, the two phase flow is separated with the steam directed to the vaporizer and the separated bring to the preheater. The steam condensate from the vaporizer is also pumped to the preheater. The spent brine is then directed to a reinjection system. The secondary working fluid loop is similar to that in the pumped brine resource model above.